Introduction

When you think about power cables, the first thing that probably comes to mind is their ability to carry electricity from one point to another. However, there’s so much more to these essential components of our daily lives. As technology advances, the focus is shifting towards not just efficiency but also safety and environmental sustainability. Enter low-smoke halogen-free (LSHF) sheathed power cables— a mouthful, I know, but trust me, they’re worth talking about.

Understanding Low-Smoke Halogen-Free (LSHF) Sheathed Power Cables

So what exactly are these LSHF sheathed power cables? In simple terms, they are electrical cables designed to reduce the amount of smoke and eliminate toxic halogens released during a fire. These cables are made from materials that do not contain halogens such as chlorine, fluorine, bromine, and iodine.

Definition and Components

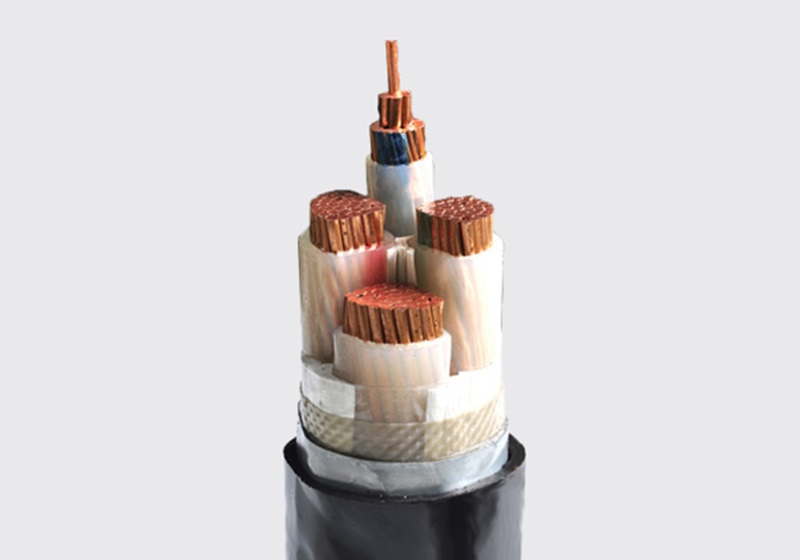

The key components of these cables include a conductor (usually copper or aluminum), insulation, a sheath made from non-halogenated materials, and sometimes an additional layer for extra protection. The “low-smoke” part means that if these cables catch fire, they will emit significantly less smoke compared to traditional cables.

- Conductor: The core of the cable, typically made from highly conductive materials like copper or aluminum.

- Insulation: A layer that covers the conductor to prevent electrical leaks and short circuits.

- Sheath: Made from non-halogenated materials that ensure minimal smoke emission and zero toxic halogens.

- Additional Layers: Sometimes added for extra durability or specific functional requirements.

Why LSHF Matters

Why should you care about LSHF? Imagine a fire breaking out in a building filled with traditional cables; the smoke would be thick and potentially toxic due to the halogens released. In contrast, LSHF cables emit less smoke, making it easier to evacuate and reducing health risks.

- Safety During Fire: These cables significantly reduce the risk of inhalation injuries during a fire by emitting less smoke and no toxic gases.

- Environmental Responsibility: Halogen-free materials are more eco-friendly when disposed of or burned.

- Regulatory Compliance: Many regions now require LSHF cables to meet stricter safety regulations.

Advantages of Low-Smoke Halogen-Free Sheathed Power Cables

These advanced cables come with a plethora of benefits that make them increasingly popular in various settings.

Safety Benefits

First and foremost, LSHF sheathed power cables significantly improve safety. They reduce the risk of inhalation injuries during a fire by emitting less smoke and no toxic gases.

- Visibility: In the event of a fire, low smoke emission ensures better visibility, aiding evacuation efforts.

- Reduced Toxicity: The absence of halogens means that toxic fumes are not released, minimizing health hazards.

Environmental Impact

From an environmental standpoint, these cables are a winner too. Traditional halogenated materials can be harmful to the environment when burned or disposed of improperly. In contrast, LSHF materials are more eco-friendly.

- Lower Carbon Footprint: These materials have a smaller environmental impact throughout their lifecycle.

- Safer Disposal: Disposal of LSHF cables does not release harmful chemicals into the environment.

Enhanced Performance

Let’s not forget about performance. These cables are often more durable and reliable than their traditional counterparts, ensuring long-term efficiency.

- Durability: Enhanced resistance to wear and tear means these cables last longer.

- Reliability: Improved materials lead to better overall performance under various conditions.

Applications of LSHF Sheathed Power Cables

These cables are versatile and can be used in a wide range of settings.

Residential Use

In homes, they offer an added layer of safety, particularly in spaces like kitchens where fire hazards are more common.

- Fire Safety in Homes: Reducing fire risks in residential areas where quick evacuation is critical.

- Peace of Mind: Knowing your home wiring is safer can offer significant peace of mind.

Commercial and Industrial Applications

In commercial buildings and industrial settings, where large amounts of wiring are required, using LSHF cables can significantly reduce fire-related risks.

- Office Buildings: Ensuring the safety of occupants in large commercial spaces.

- Industrial Sites: In environments with heavy machinery and potential for electrical fires, LSHF cables provide an extra layer of safety.

Specialized Environments

Certain environments like hospitals, schools, and public transportation systems benefit immensely from these safer cable options.

- Hospitals: Ensuring that vital medical equipment remains operational during emergencies.

- Schools: Protecting young children who may not be able to evacuate quickly.

- Public Transport: Enhancing safety in crowded public spaces like subway systems and airports.

Key Standards and Regulations

You might be wondering if there are any standards governing the use of these cables. Absolutely!

International Standards

Various international bodies have set standards to ensure the quality and safety of LSHF sheathed power cables. For instance, the International Electrotechnical Commission (IEC) has several guidelines in place.

- IEC Standards: IEC 60754 specifies the requirements for halogen-free materials.

- Other International Standards: Various countries have their own regulations that align with or complement IEC standards.

Compliance and Certification

Adhering to these standards often requires rigorous testing and certification processes to ensure that the cables meet all safety criteria.

- Testing Procedures: Cables undergo extensive testing to verify low smoke emission and absence of halogens.

- Certification Marks: Look for certification marks on cable packaging as proof of compliance with international standards.

Comparison with Traditional Power Cables

How do LSHF sheathed power cables stack up against traditional ones?

Smoke Emission Levels

Traditional cables emit a lot more smoke when they catch fire, making evacuation difficult. LSHF cables emit far less smoke, improving visibility during emergencies.

- Visibility During Fire: Traditional cables can create dense smoke clouds that obscure vision, while LSHF cables ensure clearer escape routes.

- Impact on Firefighting: Lower smoke levels make it easier for firefighters to locate and extinguish fires quickly.

Toxicity and Health Risks

The halogens in traditional cables can release toxic gases when burned. LSHF cables eliminate this risk entirely.

- Reduced Health Hazards: Eliminating toxic halogens means fewer health risks for building occupants.

- Cleaner Air Quality: Improved air quality during fires helps protect both people and property.

Durability and Longevity

LSHF sheathed power cables are often more durable, providing long-lasting performance even in harsh conditions.

- Resistance to Environmental Factors: These cables often resist moisture, chemicals, and extreme temperatures better than traditional ones.

- Longevity: Longer lifespan means fewer replacements over time, saving money in the long run.

Introduction

When you think about power cables, the first thing that probably comes to mind is their ability to carry electricity from one point to another. However, there’s so much more to these essential components of our daily lives. As technology advances, the focus is shifting towards not just efficiency but also safety and environmental sustainability. Enter low-smoke halogen-free (LSHF) sheathed power cables— a mouthful, I know, but trust me, they’re worth talking about.

Understanding Low-Smoke Halogen-Free (LSHF) Sheathed Power Cables

So what exactly are these LSHF sheathed power cables? In simple terms, they are electrical cables designed to reduce the amount of smoke and eliminate toxic halogens released during a fire. These cables are made from materials that do not contain halogens such as chlorine, fluorine, bromine, and iodine.

Definition and Components

The key components of these cables include a conductor (usually copper or aluminum), insulation, a sheath made from non-halogenated materials, and sometimes an additional layer for extra protection. The “low-smoke” part means that if these cables catch fire, they will emit significantly less smoke compared to traditional cables.

- Conductor: The core of the cable, typically made from highly conductive materials like copper or aluminum.

- Insulation: A layer that covers the conductor to prevent electrical leaks and short circuits.

- Sheath: Made from non-halogenated materials that ensure minimal smoke emission and zero toxic halogens.

- Additional Layers: Sometimes added for extra durability or specific functional requirements.

Why LSHF Matters

Why should you care about LSHF? Imagine a fire breaking out in a building filled with traditional cables; the smoke would be thick and potentially toxic due to the halogens released. In contrast, LSHF cables emit less smoke, making it easier to evacuate and reducing health risks.

- Safety During Fire: These cables significantly reduce the risk of inhalation injuries during a fire by emitting less smoke and no toxic gases.

- Environmental Responsibility: Halogen-free materials are more eco-friendly when disposed of or burned.

- Regulatory Compliance: Many regions now require LSHF cables to meet stricter safety regulations.

Advantages of Low-Smoke Halogen-Free Sheathed Power Cables

These advanced cables come with a plethora of benefits that make them increasingly popular in various settings.

Safety Benefits

First and foremost, LSHF sheathed power cables significantly improve safety. They reduce the risk of inhalation injuries during a fire by emitting less smoke and no toxic gases.

- Visibility: In the event of a fire, low smoke emission ensures better visibility, aiding evacuation efforts.

- Reduced Toxicity: The absence of halogens means that toxic fumes are not released, minimizing health hazards.

Environmental Impact

From an environmental standpoint, these cables are a winner too. Traditional halogenated materials can be harmful to the environment when burned or disposed of improperly. In contrast, LSHF materials are more eco-friendly.

- Lower Carbon Footprint: These materials have a smaller environmental impact throughout their lifecycle.

- Safer Disposal: Disposal of LSHF cables does not release harmful chemicals into the environment.

Enhanced Performance

Let’s not forget about performance. These cables are often more durable and reliable than their traditional counterparts, ensuring long-term efficiency.

- Durability: Enhanced resistance to wear and tear means these cables last longer.

- Reliability: Improved materials lead to better overall performance under various conditions.

Applications of LSHF Sheathed Power Cables

These cables are versatile and can be used in a wide range of settings.

Residential Use

In homes, they offer an added layer of safety, particularly in spaces like kitchens where fire hazards are more common.

- Fire Safety in Homes: Reducing fire risks in residential areas where quick evacuation is critical.

- Peace of Mind: Knowing your home wiring is safer can offer significant peace of mind.

Commercial and Industrial Applications

In commercial buildings and industrial settings, where large amounts of wiring are required, using LSHF cables can significantly reduce fire-related risks.

- Office Buildings: Ensuring the safety of occupants in large commercial spaces.

- Industrial Sites: In environments with heavy machinery and potential for electrical fires, LSHF cables provide an extra layer of safety.

Specialized Environments

Certain environments like hospitals, schools, and public transportation systems benefit immensely from these safer cable options.

- Hospitals: Ensuring that vital medical equipment remains operational during emergencies.

- Schools: Protecting young children who may not be able to evacuate quickly.

- Public Transport: Enhancing safety in crowded public spaces like subway systems and airports.

Key Standards and Regulations

You might be wondering if there are any standards governing the use of these cables. Absolutely!

International Standards

Various international bodies have set standards to ensure the quality and safety of LSHF sheathed power cables. For instance, the International Electrotechnical Commission (IEC) has several guidelines in place.

- IEC Standards: IEC 60754 specifies the requirements for halogen-free materials.

- Other International Standards: Various countries have their own regulations that align with or complement IEC standards.

Compliance and Certification

Adhering to these standards often requires rigorous testing and certification processes to ensure that the cables meet all safety criteria.

- Testing Procedures: Cables undergo extensive testing to verify low smoke emission and absence of halogens.

- Certification Marks: Look for certification marks on cable packaging as proof of compliance with international standards.

Comparison with Traditional Power Cables

How do LSHF sheathed power cables stack up against traditional ones?

Smoke Emission Levels

Traditional cables emit a lot more smoke when they catch fire, making evacuation difficult. LSHF cables emit far less smoke, improving visibility during emergencies.

- Visibility During Fire: Traditional cables can create dense smoke clouds that obscure vision, while LSHF cables ensure clearer escape routes.

- Impact on Firefighting: Lower smoke levels make it easier for firefighters to locate and extinguish fires quickly.

Toxicity and Health Risks

The halogens in traditional cables can release toxic gases when burned. LSHF cables eliminate this risk entirely.

- Reduced Health Hazards: Eliminating toxic halogens means fewer health risks for building occupants.

- Cleaner Air Quality: Improved air quality during fires helps protect both people and property.

Durability and Longevity

LSHF sheathed power cables are often more durable, providing long-lasting performance even in harsh conditions.

- Resistance to Environmental Factors: These cables often resist moisture, chemicals, and extreme temperatures better than traditional ones.

- Longevity: Longer lifespan means fewer replacements over time, saving money in the long run.

Installation and Maintenance Tips

If you’re considering making the switch to LSHF sheathed power cables, here are some tips to keep in mind.

Proper Installation Techniques

Proper installation is crucial for maximizing the benefits of these cables. Make sure to follow all manufacturer guidelines and consider hiring professionals for complex setups.

- Follow Manufacturer Instructions: Always adhere to the specific guidelines provided by the cable manufacturer to ensure optimal performance and safety.

- Hire Professionals: For large or complex installations, it’s wise to hire certified electricians who are experienced with LSHF cables.

- Use Appropriate Tools: Make sure to use tools that are designed for LSHF cable installation to avoid damaging the cables.

Regular Maintenance Practices

Like any other electrical component, regular maintenance can go a long way in ensuring optimal performance. Periodic inspections can help identify any wear or damage early on.

- Periodic Inspections: Regularly check the cables for any signs of wear and tear, corrosion, or damage.

- Cleaning and Care: Ensure that the cables and their surroundings are kept clean to prevent any accumulation of dust or debris that could pose a fire hazard.

- Professional Servicing: Schedule professional maintenance checks at least once a year to ensure that all cables are functioning correctly and safely.

Challenges and Considerations

Despite their numerous benefits, there are some challenges to consider.

Cost Factors

LSHF sheathed power cables can be more expensive upfront compared to traditional options. However, their long-term benefits often outweigh the initial costs.

- Initial Investment: The higher initial cost can be a barrier for some, but it’s important to consider the long-term savings on maintenance and potential fire damage.

- Cost-Benefit Analysis: Conducting a cost-benefit analysis can help determine if the investment is worth it for your specific needs.

Technical Limitations

While these cables offer many advantages, they may not be suitable for all applications due to certain technical limitations like flexibility issues or compatibility with existing systems.

- Flexibility: Some LSHF cables might be less flexible than traditional ones, making them harder to install in tight spaces.

- Compatibility: Ensure that LSHF cables are compatible with your existing electrical systems to avoid any functional issues.

Future Trends in Power Cable Technology

The world of power cables is ever-evolving, with exciting innovations on the horizon.

Innovations in Materials

Researchers are constantly looking for new materials that can offer even better performance while being more eco-friendly.

- Nanotechnology: The use of nanomaterials can potentially enhance the properties of LSHF cables, making them even more efficient and durable.

- Biodegradable Materials: Future innovations may include biodegradable materials that further reduce the environmental impact.

Smart Cable Systems

Imagine cables that can monitor their own health or adjust their performance based on real-time conditions—sounds futuristic? It’s closer than you think!

- Self-Monitoring Cables: These advanced cables can detect issues like overheating or wear and tear and alert users before problems escalate.

- Adaptive Performance: Smart cables can adjust their performance based on the electrical load or environmental conditions, optimizing efficiency and safety.

Conclusion

To wrap things up, low-smoke halogen-free sheathed power cables represent a significant step forward in electrical safety and environmental responsibility. While they may come with some initial costs and technical considerations, their benefits far outweigh these challenges. As we move towards a safer and more sustainable future, embracing such innovations will undoubtedly play a crucial role.

Recap of Key Points

- Enhanced Safety: LSHF cables emit less smoke and no toxic halogens during a fire, significantly improving safety.

- Environmental Benefits: These cables are more eco-friendly, contributing to lower environmental impact.

- Versatile Applications: Suitable for residential, commercial, industrial, and specialized environments.

- Regulatory Compliance: Adhering to international standards ensures quality and safety.

- Durability and Longevity: Offering enhanced performance over traditional cables.

The Way Forward for Safer Electrical Infrastructure

As we look ahead, it’s clear that LSHF sheathed power cables will play a pivotal role in creating safer and more sustainable electrical infrastructures. Whether you’re wiring a new home, upgrading an office building, or outfitting an industrial facility, considering LSHF cables could be one of the best decisions you make. They might just be the unsung heroes you need for a safer tomorrow!

Post time: 2024-09-15