Introduction

Welcome, dear reader, to the captivating realm of mineral insulated cables (MICs), a pivotal component in the modern electrical landscape. Have you ever pondered what ensures the seamless functioning of electrical systems even in extreme environments? Picture this: cables that resist fire, water, and corrosion, akin to a superhero’s armor in the world of wiring. These are the unsung champions—mineral insulated cables—renowned for their robustness, durability, and unwavering reliability. In this article, we embark on an exploration of these extraordinary cables, unraveling their history, components, benefits, and diverse applications.

What is a Mineral Insulated Cable?

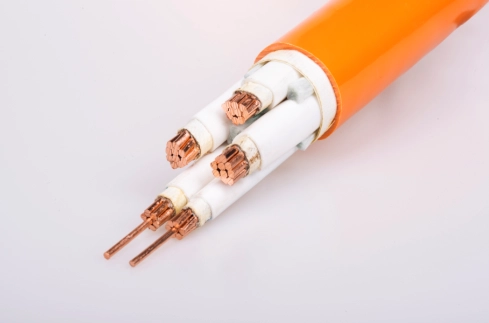

Let’s start by peeling back the layers and understanding what exactly a mineral insulated cable is. Imagine a cable as an adventurer, braving the harshest conditions without flinching. Mineral insulated cables embody this spirit. Composed of copper conductors encased within a seamless copper sheath, they are filled with magnesium oxide (MgO) powder, which acts as insulation. This unique construction allows them to perform under extreme temperatures and adverse conditions where other cables might falter. Their ability to withstand such rigors makes them indispensable in many critical applications.

History and Evolution

To truly appreciate mineral insulated cables, we need to step back in time to their origins. Developed in the early 20th century, these cables emerged from a necessity to provide reliable wiring solutions in hazardous environments. The initial designs were basic but functional, catering to industries that demanded resilience against fire and chemical exposure.

As technology advanced, so did MICs. The mid-20th century saw significant improvements in materials and manufacturing processes, enhancing their performance and expanding their use across various sectors. Today, MICs are at the forefront of electrical innovation, continuously evolving to meet the demands of modern industries while retaining their core strength—durability.

Components of Mineral Insulated Cables

Let’s delve into the heart of these cables—their components—and discover what makes them tick.

Conductors

At the core of an MIC is its conductor. Typically made from copper due to its excellent conductivity and thermal properties, these conductors are like the veins of the cable, efficiently transmitting electricity while withstanding high temperatures. Copper’s ability to maintain performance even under stress is what makes it an ideal choice for MICs. This ensures that electrical currents flow smoothly without interruptions or losses.

Insulation Materials

The real magic happens in the insulation—magnesium oxide (MgO). Imagine MgO as a resilient shield that protects the conductor from external threats. It’s an exceptional insulator capable of enduring extreme temperatures without degrading over time. This characteristic is crucial for applications where safety and reliability are paramount. The MgO not only insulates but also provides mechanical strength to the cable, making it fireproof and resistant to moisture and chemicals.

Benefits of Using Mineral Insulated Cables

Why should you care about mineral insulated cables? Let’s explore their multitude of benefits.

First and foremost is their unparalleled fire resistance. Unlike conventional cables that may succumb to flames, MICs stand firm, ensuring critical systems remain operational during emergencies. This fireproof nature makes them ideal for safety-critical applications where every second counts.

Furthermore, MICs boast impressive resistance to moisture and chemical damage. In environments where exposure to water or corrosive substances is inevitable, these cables remain unaffected, ensuring longevity and reliability. Their robust construction minimizes maintenance requirements, saving both time and resources over their lifespan.

Another advantage is their compact design. MICs are space-efficient, offering flexibility without sacrificing performance. This makes them particularly valuable in situations where space is limited but performance cannot be compromised.

Applications in Various Industries

Now that we’ve explored their components and benefits, let’s take a closer look at how mineral insulated cables shine across different industries.

Oil and Gas Industry

In the oil and gas sector, safety is paramount, and MICs are a preferred choice here. Picture this: offshore rigs battling harsh weather conditions or refineries dealing with explosive atmospheres. In such settings, reliability is non-negotiable. MICs can handle these challenges effortlessly, ensuring that critical operations continue smoothly without compromising safety protocols. They provide peace of mind by reducing downtime and enhancing operational efficiency.

Construction Industry

The construction industry has embraced MICs for their reliability and space-saving properties. Whether it’s a towering skyscraper or a cozy residential building, these cables provide a dependable solution for electrical wiring needs. Imagine building structures that must meet stringent safety standards while optimizing space—MICs fit this bill perfectly. Their ability to withstand high temperatures and harsh conditions makes them invaluable assets in construction projects worldwide.

Installation and Maintenance

Installing mineral insulated cables might sound daunting, given their robust construction, but it’s surprisingly straightforward. Picture this: you’re piecing together a complex puzzle, but each piece fits seamlessly with a little finesse. MICs are designed for easy installation due to their flexibility and compact size. They can be bent and shaped to fit into tight spaces without compromising their integrity. This flexibility is a boon during installation, allowing them to adapt to various architectural designs and layouts.

Maintenance is another area where MICs shine. Their durable construction means they require minimal upkeep. Unlike other cables that might degrade or require frequent checks, MICs are built to last. Their resistance to fire, moisture, and chemicals ensures that they remain operational without the need for constant maintenance. This not only saves time but also reduces long-term costs, making them an economical choice for many industries.

Safety Features

When it comes to electrical systems, safety is paramount. Mineral insulated cables are designed with safety in mind, offering features that make them indispensable in high-risk environments. Imagine having a guardian angel watching over your electrical systems—MICs provide that level of protection.

Fire Resistance

One of the standout features of MICs is their exceptional fire resistance. In the event of a fire, these cables do not burn or emit toxic gases, unlike conventional cables. This makes them ideal for use in safety-critical applications such as emergency lighting, fire alarms, and sprinkler systems. Their ability to maintain functionality during fires ensures that essential systems remain operational, potentially saving lives and property.

Electrical Integrity

MICs also offer superior electrical integrity. The seamless copper sheath provides excellent grounding and shielding properties, minimizing the risk of electrical interference or faults. This is crucial in environments where electrical reliability is non-negotiable, such as hospitals or data centers.

Comparison with Other Cable Types

To truly appreciate the value of mineral insulated cables, let’s compare them with other common cable types like PVC or XLPE cables.

PVC Cables

PVC cables are widely used due to their cost-effectiveness and ease of installation. However, they have limitations in terms of temperature resistance and fire safety. PVC can degrade under high temperatures and may emit harmful gases when burned, posing safety risks.

XLPE Cables

XLPE (cross-linked polyethylene) cables offer better temperature resistance compared to PVC but still fall short of the robustness offered by MICs. While XLPE can handle higher temperatures, it lacks the fireproof nature of mineral insulated cables and may not be suitable for all hazardous environments.

The Verdict

While MICs may have a higher initial cost compared to PVC or XLPE cables, their long-term benefits often outweigh these costs. The unparalleled durability, safety features, and low maintenance requirements make them a wise investment for critical applications where reliability is essential.

Future Trends in Mineral Insulated Cable Technology

As technology continues to evolve, so does the world of mineral insulated cables. Expect to see innovations that enhance their flexibility and adaptability while maintaining their core strengths.

Enhanced Flexibility

Researchers are exploring new materials and manufacturing techniques to make MICs even more flexible without compromising their durability. This could open up new possibilities for their use in complex architectural designs and intricate installations.

Environmental Sustainability

Sustainability is becoming increasingly important in every industry. Future advancements may focus on making MICs more environmentally friendly by reducing the environmental impact of their production processes or exploring recyclable materials.

Conclusion

In conclusion, mineral insulated cables are truly an unsung hero in the realm of electrical wiring. With their unmatched reliability and safety features, they play a crucial role across various industries. Whether you’re constructing skyscrapers or exploring oil fields, these cables stand ready to tackle any challenge thrown their way. By understanding their history, components, benefits, and applications, we gain insight into why they remain an indispensable choice for critical wiring solutions. As technology advances, MICs will continue to evolve, ensuring they remain at the forefront of electrical innovation for generations to come.

Post time: 2024-10-16